Steam Boiler: widely used in various industries, such as textile, chemical, paper, machinery, food, agricultural products processing industry, etc

Hot Water Boiler: widely used in hotels, schools, residential and other enterprises and institutions of heating, bathing and domestic hot water supplying

| Combustion Equipment | Chain Grate Boiler |

Steam Boiler | 2~40T/h |

Rated Working Pressure | 1.0/1.25/1.6Mpa |

Hot Water Boiler | 1.4~29MW |

Rated outlet pressure | 0.7/1.0/1.25/1.6Mpa |

Design Thermal Efficiency | ≥87.9% |

Applicable Fuel | Wood, Coal, Biomass fuels |

1.The large furnace is easy for the full combustion of biomass fuel. According to the combustion characteristics of biomass fuel, the furnace arch is designed reasonably to improve the burn out degree of fuel and eliminate black smoke.

2.The use of high-strength large grate pieces is suitable for the transportation and combustion of biomass fuel. The installation of roller device for large grate can improve the safety of grate and facilitate combustion adjustment.

3.The unique feeding device has strong fuel adaptability to prevent front combustion and upper combustion of furnace fire.

4.The unique secondary air supply device blows the flame back to prevent the flame from channeling into the hopper,strengthens the flue gas disturbance, promotes combustion and prevents the generation of black smoke.5.The heating surface and combustion device are arranged reasonably, and the thermal efficiency of the boiler is increased by2%-5%.

6.Reasonable smoke speed design, no ash accumulation and wear on the heating surface, so as to ensure the long-term efficient and stable operation of the boiler.

7.The inertia separation design of smoke and dust at the furnace outlet can effectively reduce the dust concentration in smoke exhaust and reduce the wear of rear heating surface.

8.Large water volume is conducive to power failure protection and strong adaptability to load change.

9.Compact structure, small installation dimension, shorten installation period and reduce the cost of boiler room.

10.Hot water boiler: independent circuit design and reasonable injection cycle are adopted to ensure reliable operation.

| Technical Parameters | DZL-15 -1.25-SC1 | DZL-15 -1.6-SC1 | DZL-20 -1.25-SC1 | DZL-20 -1.6-SC1 | DZL-30 -1.6 | DZL-30 -1.62 | DZL-35 -1.6 | DZL-35 -1.62 | DZL-40 -1.25 | DZL-40 -1.6 | ||

| Rated evaporation capacity | 15 | 15 | 20 | 20 | 30 | 30 | 35 | 35 | 40 | 40 | ||

| Rated working pressure | 1.25 | 1.6 | 1.25 | 1.6 | 1.25 | 1.6 | 1.25 | 1.6 | 1.25 | 1.6 | ||

| Feed water temperature | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | 105 | ||

| Rated steam temperature | 193.4 | 204 | 193.4 | 204 | 193.4 | 204 | 193.4 | 204 | 193.4 | 204 | ||

| Radiant heating area | 39.5 | 39.5 | 52.68 | 52.68 | 59.4 | 59.4 | 64.7 | 64.7 | 66.05 | 64.7 | ||

| Convective heating area | 348.1 | 348.1 | 471.1 | 471.7 | 638.6 | 638.6 | 962.3 | 962.3 | 967.3 | 962.3 | ||

| Effective area of grate | 15.56 | 15.56 | 22.7 | 22.7 | 26.6 | 26.6 | 29.3 | 29.3 | 34.5 | 29.3 | ||

| Applicable fuel | SC | SC | SC | SC | SC | SC | SC | SC | SC | SC | ||

| Temperature of exhaust gas | 125.9 | 129.9 | 122.1 | 127 | 122.1 | 127 | 124.2 | 129 | 123.2 | 128 | ||

| Design thermal efficiency | 84.7 | 84.4 | 84.9 | 84.5 | 87.9 | 87.4 | 87.8 | 87.3 | 87.8 | 87.3 | ||

| Fuel consumption | 2452 | 2468 | 3902 | 3960 | 5399 | 5476 | 6260 | 6410 | 7096 | 7210 | ||

| Maximum transport weight | 24/21 | 24/21 | 30 | 30 | 28.1 | 30.1 | 33.6 | 35.2 | 37.6 | 38.6 | ||

| Maximum transport size | 7.35×3.2×3.5 | 8.5×3.1×2.6 | 7.35×3.2×3.5 | 8.5×3.1×2.6 | 9.8×3.7x3.6 | 9.8×3.7 x3.6 | 9.1×4.2×3.5 | 9.1×4.2x3.5 | 8.56×2.55x2.7 | 8.56×2.55×2.7 | 8.56×2.6×2.9 | 8.56×2.6x2.9 |

| Installation dimension | 10.5×6.0x7.8 | 10.5×6.0×7.8 | 10.7×6.5×8.51 | 10.7×6.5x8.51 | 11.2×8.0×9.3 | 11.2×8.0 x9.3 | 13.2x8.90x9.6 | 13.2×8.90x9.6 | 14.2×9.4x9.6 | 14.2×9.4x9.6 |

* The above product data is for reference only. Please refer to the actual product and product manual for specific information. Unless otherwise specified, all data interpretation rights involved in this website belong to CJSE.

We offer a diverse range of transportation options, including bulk cargo shipping and container shipping. For bulk cargo shipping, we use tarpaulins and cargo nets to package the tanks, ensuring moisture and corrosion resistance, providing worry-free safety. You can choose from ocean shipping, land transportation, or railway transportation based on your needs.

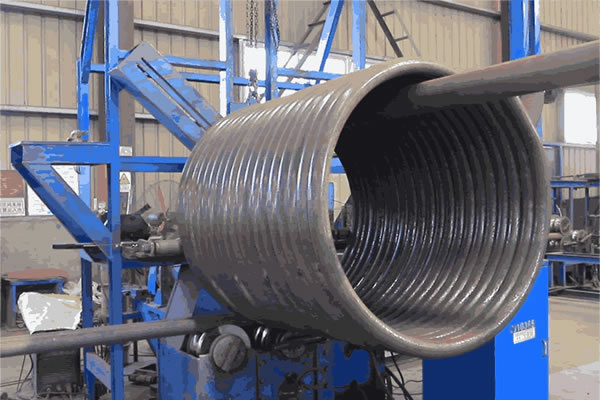

We have over 600 advanced production machines, providing a solid foundation for product manufacturing. The manufacturing process involves more than ten steps, including cutting, head pressing, rolling, longitudinal and circumferential seam welding, assembly welding, machining, heat treatment, hydrostatic testing, sandblasting, painting, and more. Each step is staffed with skilled professionals, and further subdivided to enhance efficiency and product quality.

As the national standard drafting unit, our company stands out in Shandong's manufacturing scene, winning the title of Provincial Manufacturing Single Champion Enterprise. Not only are we recognized as a nationally accredited "Little Giant" enterprise specializing in innovation, but our products and services have also obtained international authoritative certifications such as ASME, CE, ISO, and EAC, showcasing our competitiveness and commitment to quality in the global market. To ensure top-notch quality, we willingly undergo evaluations by trusted third-party agencies like BV, SGS, TUV, and more. This guarantees our customers get the safest, most reliable products and services.

Our personnel have participated in exhibitions in more than 20 countries, and our customers are spread across over 60 countries and regions.

30+ Global Top 500 enterprises cooperation experience such as Air Liquide, Coca Cola, Sinopec and so on.