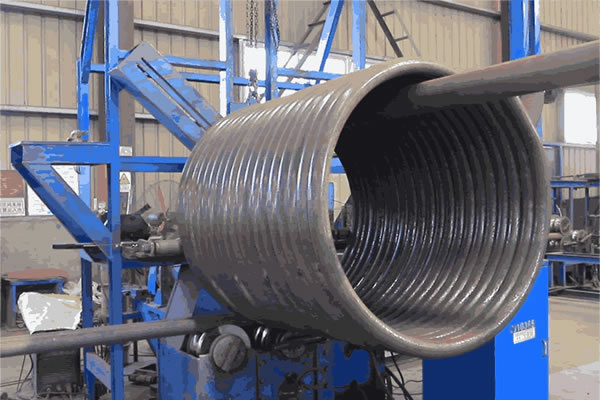

The YGL type biomass thermal oil furnace uses biomass particles as fuel and thermal oil as the medium. It uses a circulating oil pump to force the thermal oil to circulate in the liquid phase. It transfers heat energy to the heating equipment and then returns to the heating furnace for reheating. This forced circulation vertical biomass boiler is an ideal heating equipment. It adopts a three-pass coil design, with sufficient heating surface and full absorption of expansion, achieving low-pressure and high-temperature heating. It can also add an energy saver to make the boiler more energy-efficient to operate, and can serve all walks of life more efficiently and energy-savingly.

1.Under lower operating pressure, higher working temperature can be obtained, which has the technical characteristics of low pressure and high temperature

2.It has perfect automatic control and safety monitoring device;

3.It has good thermal stability and accurate temperature conditions

4.Closed cycle heating is adopted, with high heat utilization efficiency and remarkable energy-saving effect.

| model number | YGL-700 | YGL-1000 | YGL-1400 | YGL-1800 |

| Rated thermal power(MW) | 0.7 | 1.0 | 1.4 | 1.8 |

| Rated working pressure(Mpa) | 0.6 | 0.6 | 0.8 | 0.8 |

| Maximum outlet temperature(℃) | 320 | 320 | 320 | 320 |

| Rated oil supply temperature ℃ | 250 | 250 | 250 | 250 |

| Rated oil return temperature ℃ | 230 | 230 | 230 | 230 |

| Thermal efficiency (%) | ≥82 | ≥82 | ≥82 | ≥82 |

| Boiler oil capacity (m³) | 0.6 | 0.8 | 1.2 | 1.6 |

| Circulating oil capacity (m³/h) | 55 | 80 | 116 | 150 |

| Maximum transport weight | 4.65 | 4.97 | 6.82 | 7 |

* The above product data is for reference only. Please refer to the actual product and product manual for specific information. Unless otherwise specified, all data interpretation rights involved in this website belong to CJSE.

We offer a diverse range of transportation options, including bulk cargo shipping and container shipping. For bulk cargo shipping, we use tarpaulins and cargo nets to package the tanks, ensuring moisture and corrosion resistance, providing worry-free safety. You can choose from ocean shipping, land transportation, or railway transportation based on your needs.

We have over 600 advanced production machines, providing a solid foundation for product manufacturing. The manufacturing process involves more than ten steps, including cutting, head pressing, rolling, longitudinal and circumferential seam welding, assembly welding, machining, heat treatment, hydrostatic testing, sandblasting, painting, and more. Each step is staffed with skilled professionals, and further subdivided to enhance efficiency and product quality.

As the national standard drafting unit, our company stands out in Shandong's manufacturing scene, winning the title of Provincial Manufacturing Single Champion Enterprise. Not only are we recognized as a nationally accredited "Little Giant" enterprise specializing in innovation, but our products and services have also obtained international authoritative certifications such as ASME, CE, ISO, and EAC, showcasing our competitiveness and commitment to quality in the global market. To ensure top-notch quality, we willingly undergo evaluations by trusted third-party agencies like BV, SGS, TUV, and more. This guarantees our customers get the safest, most reliable products and services.

Our personnel have participated in exhibitions in more than 20 countries, and our customers are spread across over 60 countries and regions.

30+ Global Top 500 enterprises cooperation experience such as Air Liquide, Coca Cola, Sinopec and so on.